In many applications, coating carbon can provide a variety of advantages. We will discuss some of the major benefits of covering carbon in this response, such as increased tensile strength, corrosion resistance, and electrical conductivity. Certain definite advantages are provided by carbon coatings. Amorphous, transparent electrons carbon coatings are used in electron microscopy. This suggests that carbon coatings are especially useful for enabling energy-dispersive x-ray spectroscopy (EDS) of non-conductive samples

- Durability: Carbon coatings may make a variety of materials more resilient. A substance can be shielded from deterioration, abrasion, and environmental harm by having carbon coated on its surface. For high-wear applications including cutting tools, aerospace parts, and medical implants, carbon coatings can be extremely helpful.

- Corrosion Resistance: Carbon coatings can help a variety of materials resist corrosion. To assist stop oxidation and rust, the carbon coating may serve as a barrier between the material and the corrosive environment. This makes it ideal for a variety of uses, including infrastructural components, automotive parts, and maritime and offshore equipment.

- Enhanced Electrical Conductivity: Carbon coatings have the ability to improve a variety of materials’ electrical conductivity. A material’s conductivity can be increased by covering it with carbon, which is a superb conductor of electricity. This makes it practical for uses like electronics, which demand strong conductivity.

- Thermal Conductivity: Carbon coatings can also improve a material’s capacity to conduct heat. A material’s thermal conductivity can be increased by covering it with carbon, which is a good thermal conductor. This makes it practical for uses like thermal management systems and heat sinks.

- Lubrication: Different materials may benefit from the lubrication that carbon coatings can offer. Carbon can be used to coat a material’s surface to lessen wear and friction between two surfaces. Because of this, it can be used to moving elements like bearings and gears.

- Aesthetic Appeals: Carbon coatings can also enhance the aesthetic appeal of a variety of materials. The distinct appearance and feel of carbon can improve a material’s appearance. Because of this, it can be used in products like high-end watches, jewelry, and automobile parts.

- Biocompatibility: Carbon coatings can make a variety of materials biocompatible. Carbon is a biocompatible substance, and covering a substance with it can help make it more biocompatible. Due to this, it can be used in medical applications such surgical instruments, orthopedic implants, and dental implants.

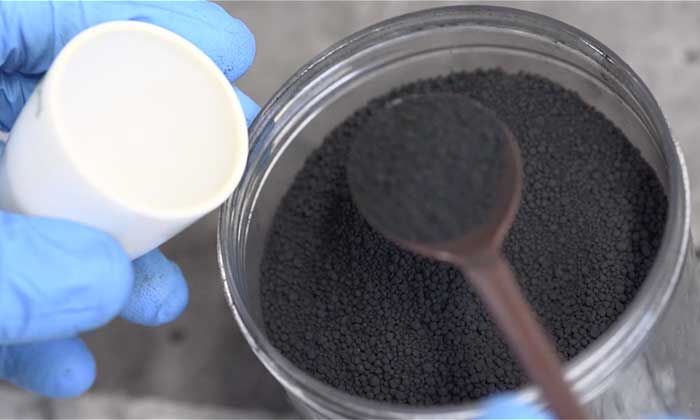

- With sustainable carbonaceous materials that meet your industrial coating needs’ requirements for good color performance and flow qualities, you may strengthen your sustainability initiatives and come closer to your net zero aim. Our environmentally friendly materials have good opacity at low loadings and can be used for a variety of purposes, such as tinting.

- Appearance: By maximizing your mix of particle size and surface treatment, you may fine-tune your melt flow and improve surface smoothness. Our speciality portfolio includes both treated and untreated goods.

- With the help of our Nano Technology, Carbon Coat can cover any microfine flaws in the paintwork, decreasing light refraction and giving the paintwork an unsurpassed sheen with only one application.Birla Carbon offers a full line of high performing tinting carbon blacks. The necessary color and tone performance, as well as the best system compatibility and dispersibility, are all provided by these goods.

- By choosing from a wide selection of Raven carbon blacks, you may achieve the tinting strength and tonal performance you want. Their meticulously designed morphologies satisfy your selected tint strength while offering a distinct, aesthetically pleasing blue undertone.

- Our products enable you to improve your formulations toward contemporary dispersion agents in solvent and water borne formulations and provide you with universal systems compatibility, simple dispersion, blue undertones, and. In addition to improving color performance, improved product performance and dispersability also provide significant cost and production time reductions..

Finally, covering carbon can have a number of advantages in a variety of uses. Carbon coatings have many benefits, including increased sturdiness, corrosion resistance, electrical conductivity, and aesthetic appeal.

Here are some of the tips why and how to choose carbon ceramic coating:

- The desired use, the coating’s characteristics, and the coating’s quality should all be taken into account when selecting a carbon coating. Here are some suggestions to assist you in selecting the best carbon coating:

- Recognize the Application: Recognizing the intended application is the first step in selecting a carbon coating. The environment in which the material will be used, the wear and tear it will endure, and the necessary characteristics, such as electrical conductivity, thermal conductivity, and corrosion resistance, should all be taken into account.

- Selecting the Correct Carbon Coating Type: Diamond-like carbon (DLC), amorphous carbon, and graphene are some of the different types of carbon coatings that are available. It is crucial to select the appropriate type for your application because each has different characteristics and benefits.

- Check the Coating’s Quality: The carbon coating’s quality should also be taken into account. Look for coatings that have undergone testing and received certification from reliable agencies. Check the coating’s consistency, thickness, and adhesion to the substrate, as well.

- Finally, take into account the expense of the carbon coating. Although premium coatings may cost more up front, they can perform better and last longer in the long term, which can result in financial savings. When selecting a carbon coating, take into account the entire cost of ownership, which includes maintenance and replacement costs.

The portfolio of Birla Carbon provides a wide range of morphologies and surface functionalities to fulfill even the most demanding needs in various systems and applications.

The top sustainable producer and supplier of carbon black additives in the world is Birla Carbon. Our carbon black is of the greatest quality anywhere it is sold because to our global presence, which guarantees a consistent product wherever our clients are. Birla Carbon is the ideal partner with the right product for optimum performance in any application for tires, specialized blacks, and mechanical rubber goods, whether it is a known formulation or a new solution.

Our product line includes a variety of options for jetness, melt flow, and coating look. With or without surface modification, our high surface area solutions deliver good jetness and tone performance. You can also benefit from the UV stability of our high-color carbon black materials when using full-shade coatings.